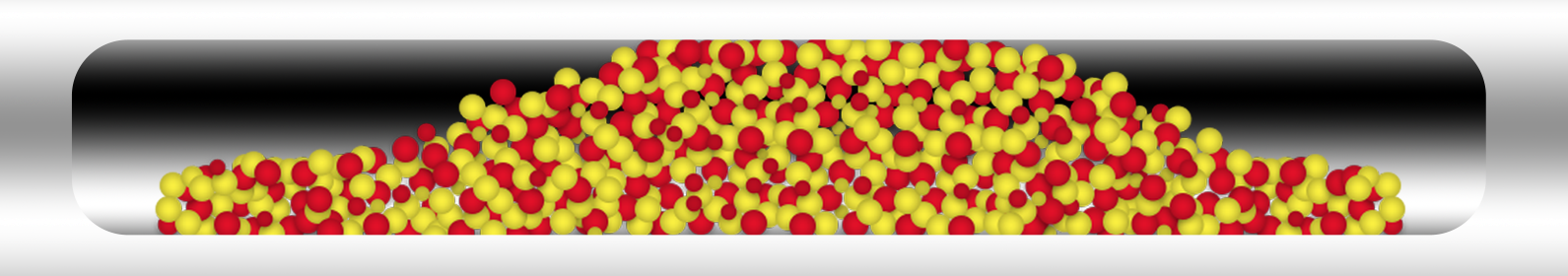

In dense phase conveying, we've got two ways things move along. First up, there's the "moving bed flow," where the material travels in little dunes along the bottom of the pipeline. It's kind of like watching sand dunes form in a desert, but inside a pipeline. Then there's the "slug" or "plug" type flow, where the material moves in big chunks separated by air gaps. You might catch a glimpse of this if you look through a sight glass in a horizontal pipeline – it's like seeing solid blocks of stuff make their way through.

In vacuum dense phase conveying, a vacuum is applied at the receiving end of the pipeline system, creating a pressure gradient that draws the material through the pipeline. This method is particularly suitable for transporting materials that are prone to degradation or abrasion, as it minimizes the exposure of the material to air and reduces the risk of particle breakdown.

Pressure dense phase conveying involves the use of positive pressure to push the material through the pipeline. This method is often preferred for materials that require gentle handling or for longer conveying distances where maintaining material integrity is critical. By controlling the pressure within the pipeline, operators can adjust the conveying velocity and ensure optimal transportation of the material.

Both vacuum and pressure conveying systems in dense phase conveying require careful design and control to ensure efficient operation and minimal material degradation. Proper selection of pipeline diameter, air velocity, and conveying pressure is essential to achieve the desired conveying performance while minimizing energy consumption and wear on system components.

At Pneumatic Conveyor Insight, we specialize in tackling the complex challenges associated with transporting powders, granules, and bulk solids through pneumatic conveying systems. Our expertise lies in devising effective solutions tailored to your unique requirements and operational constraints.

Understanding the critical importance of selecting the right systems supplier, we are committed to providing unbiased recommendations. Our approach involves in-depth analysis and evaluation, ensuring that we match you with the most suitable suppliers in the industry. Leveraging our extensive network and expertise, we guarantee impartial guidance, connecting you with top-tier suppliers capable of delivering optimal solutions for your specific needs.

Your satisfaction and success are paramount to us at Pneumatic Conveyor Insight. Trust us to navigate the complexities of pneumatic conveying systems and facilitate connections with suppliers who can offer reliable, efficient, and customized solutions, perfectly aligned with your unique challenges.

Email Us