Dilute phase suspension flow is a versatile and efficient method for conveying materials through pipelines. By understanding the principles behind this method and considering factors like particle behavior, material properties, and pipeline design, industries can optimize their conveyance processes and ensure the safe and efficient movement of materials.

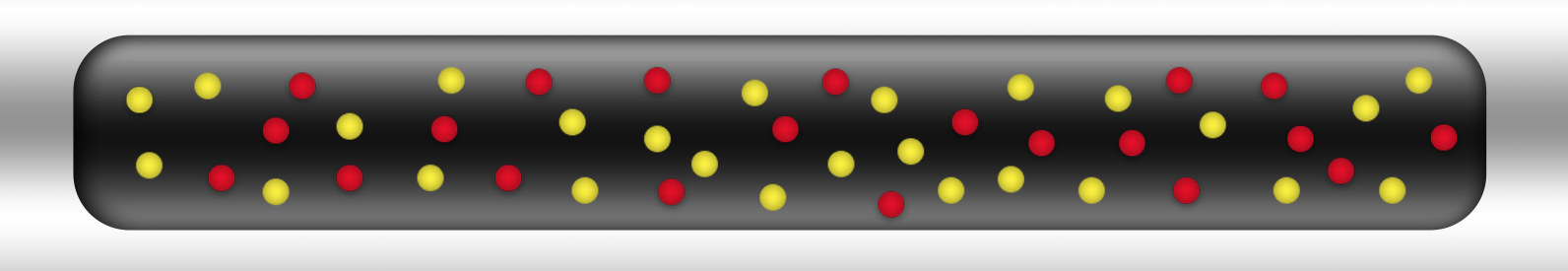

Dilute Phase Pneumatic Vacuum Conveying Bulk Pneumatic Conveying uses a vacuum as conveying force. The material is trapped in a high-speed air stream and moved through a pipeline to the final destination. A vacuum pump or a blower creates a vacuum that pulls the air and the material through the pipe. Dilute phase Pneumatic is commonly used for the transportation of fine powders or granular materials over small to medium distances. Dilute Pneumatic is widely used in industries like food processing, pharmaceutical, and chemical processing where delicate handling and low product degradation are important.

Dilute phase Pneumatic Pressure Conveying is a method of conveying bulk materials by using compressed air as a conveying force. The material is immersed in a high-speed air stream and moved through a pipeline to the final destination. The pressure generated by the compressor or blower pushes the air and materials through the pipeline. Dilute phase pressure conveying is mainly used for the transportation of fine powders or granular materials over small to medium distances. This method is widely used in industries like food processing, pharmaceutical, and chemical processing where delicate handling and low product degradation are important.

Both vacuum and pressure conveying systems in dilute phase conveying require careful design and control to ensure efficient operation and minimal material degradation. Proper selection of pipeline diameter, air velocity, and conveying pressure is essential to achieve the desired conveying performance while minimizing energy consumption and wear on system components.

At Pneumatic Conveyor Insight, we specialize in tackling the complex challenges associated with transporting powders, granules, and bulk solids through pneumatic conveying systems. Our expertise lies in devising effective solutions tailored to your unique requirements and operational constraints.

Understanding the critical importance of selecting the right systems supplier, we are committed to providing unbiased recommendations. Our approach involves in-depth analysis and evaluation, ensuring that we match you with the most suitable suppliers in the industry. Leveraging our extensive network and expertise, we guarantee impartial guidance, connecting you with top-tier suppliers capable of delivering optimal solutions for your specific needs.

Your satisfaction and success are paramount to us at Pneumatic Conveyor Insight. Trust us to navigate the complexities of pneumatic conveying systems and facilitate connections with suppliers who can offer reliable, efficient, and customized solutions, perfectly aligned with your unique challenges.

Email Us