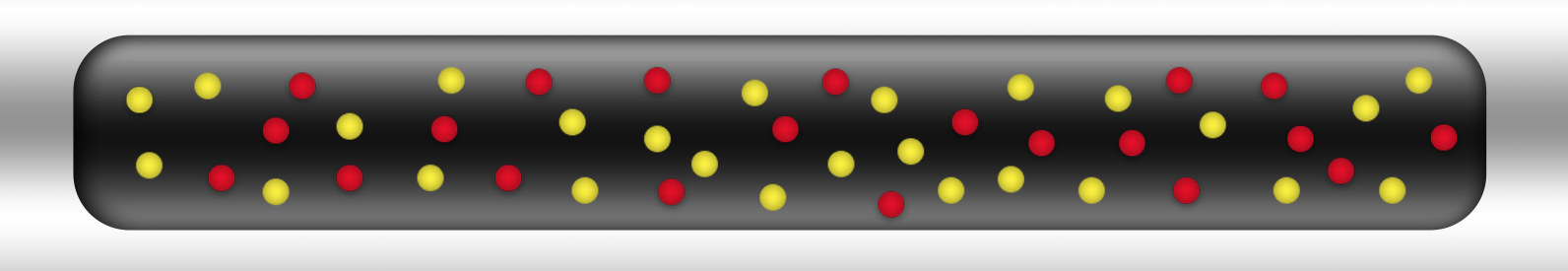

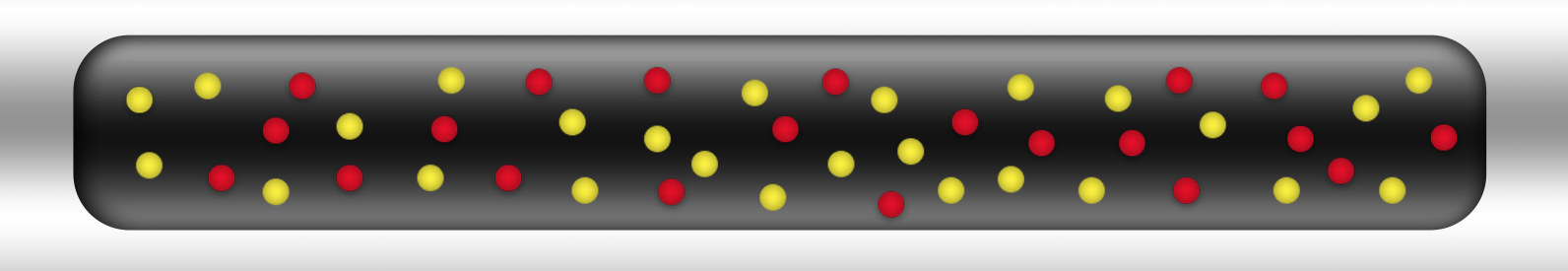

Dilute Phase Conveying:

In this system, the material is suspended in the air or gas stream, and it moves in a dispersed, low-concentration phase. This is suitable for conveying lighter materials over longer distances.

READ MORE

Pneumatic conveying is a method of transporting bulk materials (powder, granules, or other dry bulk solids) from one place to another using a gas or air stream as the conveying medium. This technique is widely used in various industries such as plastics polymer, food processing, pharmaceuticals, agriculture, chemicals, and manufacturing.

In this system, the material is suspended in the air or gas stream, and it moves in a dispersed, low-concentration phase. This is suitable for conveying lighter materials over longer distances.

READ MORE

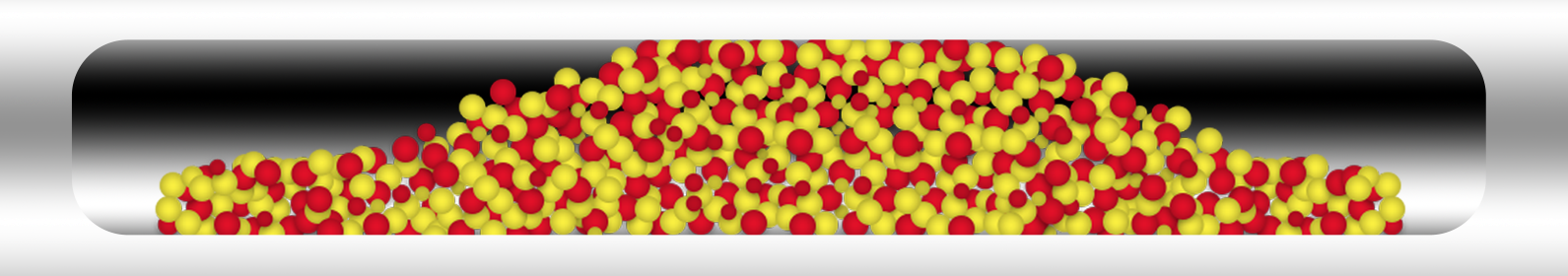

Here, the material is conveyed in a dense, high-concentration phase, with the particles closely packed together. Dense phase conveying is often used for heavier or more abrasive materials, and it typically operates at lower velocities.

READ MORE| Characteristic | Dilute Phase Pneumatic Conveying | Dense Phase Pneumatic Conveying |

|---|---|---|

| Air Pressure | Low pressure: 0.1 bar to 1 bar for pressure systems and (-)0.1 bar to (-)0.5 bar for vacuum systems | High pressure: 1 bar to 5 bar for pressure systems and (-)0.5 bar to (-)0.95 bar for vacuum systems |

| Air Velocity | High - 15 m/s to 25 m/s | Low - 3m/s to 12 m/s |

| Material-to-Air Ratio | Low - 1 to 10 | High - 5 to 100 |

| Material Behavior | Material is suspended in the airstream | Material moves in a more cohesive manner |

| Conveying Rates | Suitable for high conveying rates | Suitable for lower conveying rates |

| Material Suspension | Material is fully or partially suspended | Material is conveyed as a dense mass |

| Pressure Drop | Low | High |

| Applications | Commonly used for lightweight materials, powders, and granules | Commonly used for abrasive or fragile materials, bulk powders, and granules |

| Conveying Distance | Suitable for long distances | Suitable for shorter distances |

| Energy Requirements | Lower energy consumption | Higher energy consumption |

| Common Industries | Food processing, plastics, chemicals, etc. | Minerals processing, cement, foundries, etc. |

or contact us via info@pneumaticconveyingsystem.com